Showing 41–57 of 57 results

-

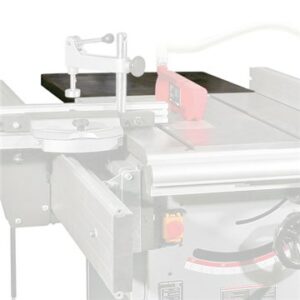

01495 Optional Sliding Table for 01332 SIP Cast Iron Table Saw

£639.99 Inc. VAT View Product -

SIP 01446 12″ Cast iron Table Saw 100mm Depth of Cut (shown with optional sliding table and rear extension table)

£2,464.99 Inc. VAT View Product -

01447 Optional Sliding Table for 01446 SIP Cast Iron Table Saw (01446)

£705.90 Inc. VAT View Product -

SIP 06920/T Wheel Kit for 01480, 01332 and 01446 Table saws

£106.90 View Product -

01448 Optional Rear Support Table for 01446 SIP Cast Iron Table Saw

£98.90 Inc. VAT View Product -

Draper BTS256A 250mm dia. blade Table saw bench model 1800watt motor (99258)

£239.99 View Product -

Sedgwick TA315 Table Saw complete with sliding table 1phase

View Product -

Sedgwick TA315 Table Saw complete without sliding table 1phase or 3phase.

View Product -

Sedgwick TA315 Table saw complete with sliding table 3phase

View Product -

Sedgwick TA450 Mk2 Tilting Arbor Sawbench 3phase. Get in touch for fantastic prices.

View Product -

Tigren 08210 Contractor saw 12″ (315mm) dia blade 2.2 kw motor 230volt 13amp

£312.79 Inc. VAT View Product -

Charnwood TB1248 TCT Saw Blade 300mm x 30mm x 48T x 3.2k

£35.50 View Product -

Charnwood TB0840 TCT Saw Blade 200mm x 30mm x 40T x 2.6k

£28.50 View Product -

Charnwood TB1024 TCT Saw Blade 250mm x 30mm x 24T x 3.0k

£25.00 View Product -

SIP 01383 Adjustable V Roller Ball Stand

£62.90 Inc. VAT View Product -

SIP 01381 Heavy-Duty 5 Roller Stand

£114.90 Inc. VAT View Product -

SIP 01379 Collapsible Single Roller Stand

£58.90 Inc. VAT View Product

Which table saw is the best?

The best table saws for you depend on the type of project you’ll be working on, how much space you have in your workshop, and how much you can afford to spend.

For example, if you do a lot of heavy-duty work, such as cutting large pieces of timber, you’re going to need a table saw with a powerful motor. Contractor table saws tend to have larger motors than benchtop saws and can handle a multitude of tasks.

Alternatively, if your workshop is only small or you only need one for light-duty tasks, the last thing you want to do is opt for table or bench saws with a large footprint. Instead, go for a portable or benchtop model that can be easily moved around the room or used for mobile jobs, such as trimming branches and cutting wood.

If you’d like to know more about the table saw range we supply here at Kendal Tools, don’t hesitate to get in touch. We can guide and advise you on the best saw for your needs – taking into account your project requirements, space, and budget.

Are saw benches expensive?

The cost of a benchtop saw can vary anywhere from a few hundred pounds to thousands of pounds – depending on the type, brand, size, and features.

Luckily, we stock a wide range of saw benches and table saws here at Kendal Tools, so we are confident that we can offer something for your budget.

Be sure to browse our online collection in full and click through to find out more about each saw’s specifications. All of our prices are inclusive of VAT, too, so you don’t need to worry about incurring any extra costs when you purchase a saw from us.

To find out more about the cost of our benchtop saws or a compatible saw blade, give us a call on 01539 733 774 – a member of our friendly team will happily assist.

Is it easy to adjust the blade height on a table saw?

Yes, once you know how, it’s easy to adjust the height of the blade on your table saw.

- To start, make sure that your table saw is switched off completely.

- It’s then a matter of spinning the wheel at the front in the direction you want the blade to go – usually anticlockwise to lower the blade to the table, and clockwise to raise it.

You may wish to use a combination square to make sure the table saw blade is at the desired height for the task. However, as a general rule of thumb, the blade height should be no more than a tooth size above the cutting material to ensure clean, safe, and accurate cuts.

For more tips on using a benchtop saw safely, talk to our experts today.

How do I use a bench saw safely?

Much like any other large power tool, a saw can be dangerous if it’s not used correctly, thanks to the powerful motor. This is why you must always wear the appropriate safety gear when the table saw is operational, including goggles and hearing protection.

When using a table saw, you need to make sure the blade diameter is set at the appropriate height to protect your fingers if your hand slips. This should be no more than 6mm above the height of the piece you’re cutting.

Likewise, it could be worth making a push stick to guide the wood through the blade, too, as this will keep your hands free of the blade.

You also need to make sure that the tabletop is clear of any obstructions, and if you’re making long or deep cuts, support the workpiece to ensure it doesn’t fall off the back of the table or into the blade.

Similarly, cleaning and lubricating the table saw and any coordinating blade will also keep them in good working order and prevent build-up, keeping hazards to a minimum.