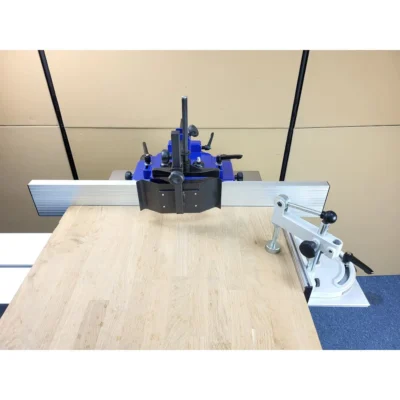

A capable spindle moulder with a cast iron main table and an aluminium sliding table. The features of this machine provide extra versatility which will suit both hobby and professional users.

Sitting in the middle of our range, between hobby and trade options, this spindle moulder offers a very versatile package.

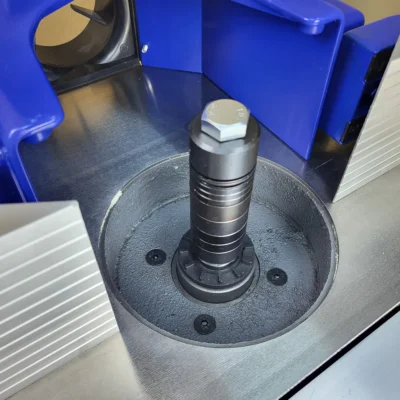

The 30mm spindle accepts all kinds of tooling up to a maximum of 150mm diameter. The spindle height can be accurately adjusted using a large handwheel and locked in place at the desired height. The current height can be read off a scale marked in metric and imperial scales. The spindle has a generous vertical stroke of 110mm.

A spindle rotation lock can be engaged when changing the tooling.

The top spindle is removeable and can be replaced with a routing spindle. Collets are included for using 1/4″ and 1/2″ Diameter shank cutters.

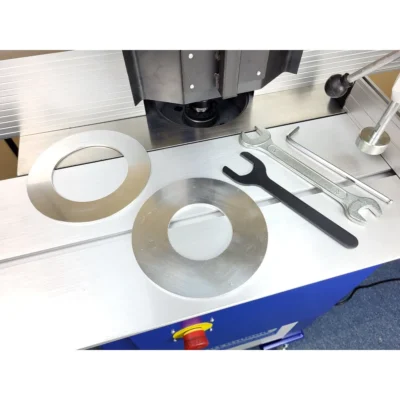

2 Insert rings are provided to reduce the aperture size when working with smaller diameter tooling or router bits.

There are 4 speed options:

- 1400rpm For Drum Sanding

- 4000rpm For Moulding in Hardwood

- 6000rpm For Moulding In Softwood

- 8000rpm For Routing

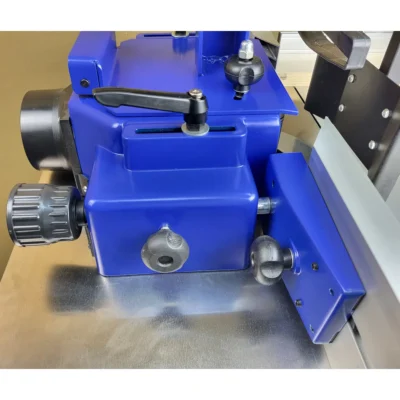

The speed is adjusted using a simple belt change. There is a digital read out to display the current speed setting to avoid any doubt. Access to the pulleys for speed changes is through a hinged door, fitted with a safety cut out to prevent accidental running whilst being worked on.

The option to run the spindle in reverse direction (and feed the timber through in the opposite direction too) allows cutter blocks to be installed upside down giving additional profiles from existing tooling. The sliding table fence and clamp can also be installed in reverse.

The cutter block hood is made from cast iron.The 2 aluminium fences mount onto the hood and are adjustable left and right. both fence are also adjustable forwards to allow a work piece to be fully supported, even when the complete face is being removed. The fence can be set behind the centre line of the spindle and up to 75mm in front of the spindle. The top of the hood hinges up to allow quick access when changing tooling.

An adjustable plastic pressure pad holds the work piece down against the table. When edge moulding or working with smaller pieces a metal plate holds the work piece up against the fence and double as a safety guard.

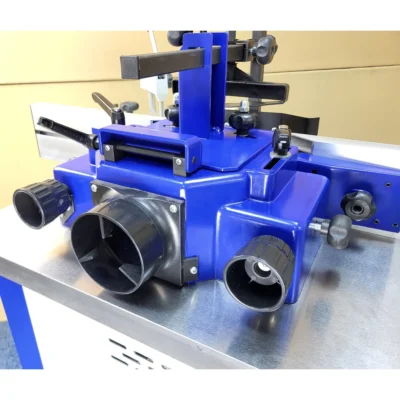

A 100mm diameter dust extraction outlet sits at the back of the hood. The bottom of the table aperture is sealed to prevent dust from getting into the internal workings of the machine and provide efficient dust and chip extraction.

The large sliding table can be used for panel work or cutting tenons. It slides smoothly on bearings and has fence at one end. The fence can be adjusted 60 degrees each way for cutting mitred pieces. There is also a work clamp which operates by a lever. When the sliding carriage is not required, the fence can quickly be removed and the table locked in a stationary position

Supplied with 30mm spindle spacer set, table inserts 75mm & 105mm, routing collets 1/4″ & 1/2″, 22mm spanner for routing collets, 24mm spanner for spindle bolt, 32mm spanner for top spindle removal, 1.75m power cable, UK 3 pin plug.

Optional Items:

SMRF: The optional Ring Fence allows safe working when putting an edge moulding onto curved shaped pieces. It consists of a round fence to control the depth of cut, a transparent cutter guard, a lead in guide and a 100mm diameter extraction outlet. The W045 table is pre-drilled ready to accept the ring fence.

W030SD: Sanding drum kit for the 30mm spindle with 3 different diameters of sleeve: 40mm / 52mm / 78mm

W522: Universal Wheel base with foot pedal operation allows the machine to be effortlessly moved around the workshop.

Specifications for Charnwood W045 Spindle Moulder With Sliding Table